Machined castings

Baoding Guokun can offer you the machined castings, custom machined casting, customized machhined casting, machined steel casting, machined iron casting as per your requirements.

What is investment casting?

Investment casting, also named lost-wax casting or precision casting, uses an expendable-mold process to achieve complex shapes with exceptional casting surface quality and fine casting accuracy. The precision investment casting process can provide net shape or near-net shape castings, which offer customers with significant cost savings in material, labor and machining.

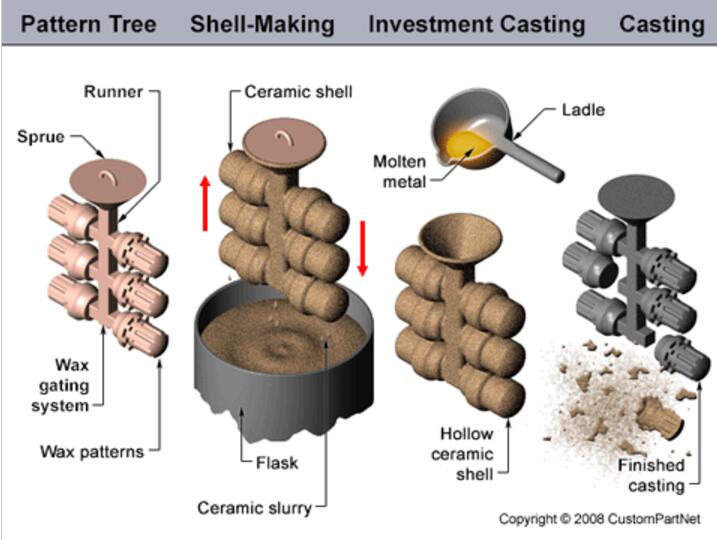

Investment Casting process

Lost wax investment casting is a manufacturing process in which a wax pattern is used to shape a disposable ceramic mold. Usually, the investment casting process consists of several steps: metal mould construction in aluminum, wax pattern production, ceramic mold creation, pouring, coolling, shakeout, and finishing.

Usually we offer two different investment casting process, water glass casting and silica sol casting process.

Water glass casting method: We use domestic wax and dewax into high temperature water. Most importantly, ceramic mold material is water glass quartz sand that is very cheap locally. Therefore, the surface finish and the casting accuracy will not be so good. But it is still much better than sand casting process.

Silica sol casting method: We use high temperature wax and dewax into flash fire. Meanwhile, ceramic mold material is silica sol zircon sand that is more expensive than quartz sand. Therefore, the surface finish and casting accuracy will be very impressive. Silica sol investment casting is our main production line right now. And we also can provide you better prices as per your drawings or samples.

| No. | Water Glass Casting | Silica sol casting |

| 1. Main metal | carbon steel, cast steel, alloy steel, wear resistant steel, etc | Stainless steel, alloy steel, etc |

| 2. Casting tolerance | CT7-CT9 | CT5-CT6 |

| 3. Surface Finish | 12.5 | 6.3 |

| 4. Application | valve casting, mining casting, agricultural casting, railway casting, etc | Furniture or door casting, medical casting, valve casting, etc |

| 5. Advantage | Competitive prices | Fine surface finish and high precision |

Investment casting advantages or benefits

- Almost any metal can be casted, such as stainless steel, carbon steel, alloy steel, wear-resistant steel, aluminum alloys, bronze alloys, brass alloy investment casting, alloy castings, zinc investment casting, etc

- Excellent Surface Finish: 50-125 uin, much better than sand casting process

- High Dimensional Accuracy: Water glass casting process’s tolerance: CT6-8; The casting tolerance for silica sol casting process is CT4-6

- NO flash or parting lines: Compared with Hot forging or drop forging process, the precision investment casting process is without no flash and parting lines.

- Little need for secondary machining

- Can produce complex shapes

Investment Casting Defects

The common defects of precision investment casting are sand hole, gas cavity, shrinlage cavity, sand burning, burrs, insufficient pouring, etc. But Baoding Guokun Machinery has more than 15 years of casting experiences to avoid such above defects.

Investment casting materials

- Alloy Steel Investment castings: 4140, 4340, 42CrMo, etc

- Carbon Steel Investment casting: 1045, 1035, etc

- Stainless steel investment casting: 304, 316, 17-4 PH

- Bronze, brass or copper alloy investment castings

- Aluminum, zinc alloy

Investment casting applications:

The industry investment casting served is valve and pipe fittings, agricultural parts, automobile & truck parts, mining casting parts, oil & gas industry, municipal engineering, train & hsr parts, marine parts, furniture components, power electronic parts, etc

Please send your inquiry to tina@guokuncasting.com or call us 86-15168139710.

Contact Us

Baoding Guokun Export and Import Trading Co., Ltd

Add: 777# Chaoyang South Street, Baoding City, Hebei, 071000, China

Factory Address: Wangdu County, Baoding City, Hebei, 071000, China

Tel: 86-312-5951319 Phone:86-18132789710(Same with WhatsApp, Wechat)

Fax: 86-312-5951296

Email:

Tina: tina@guokuncasting.com

Gina: gina@guokuncasting.com

Doris: doris@guokuncasting.com